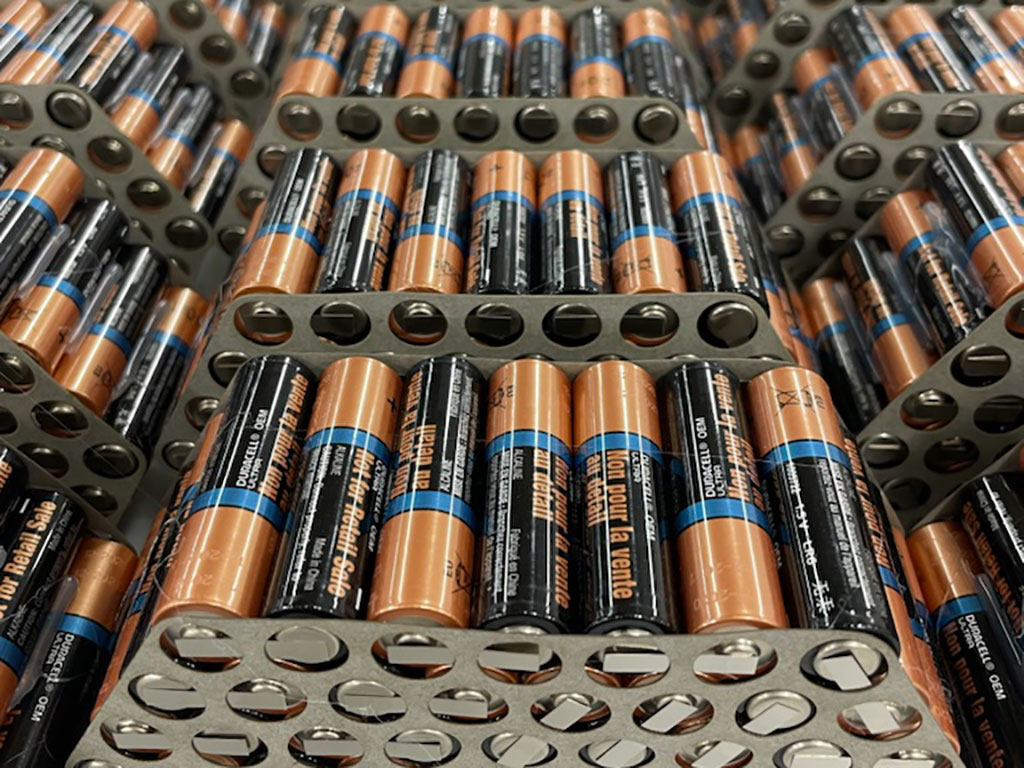

Battery pack design and assembly is our business. Adcour designs and manufactures custom battery packs for a broad range of industries and applications.

Adcour is a value-add design and manufacturing company specializing in custom and build-to-print battery systems of all chemistries, with a primary focus on Lithium Ion, LiPo, NiMH, Alkaline, and NiCd. Using the most advanced electronic design tools available, in-house engineers work closely with our customers to design to their exact specifications and optimize the manufacturability, safety and reliability of their custom battery packs, providing the most dependable and cost-effective solution.

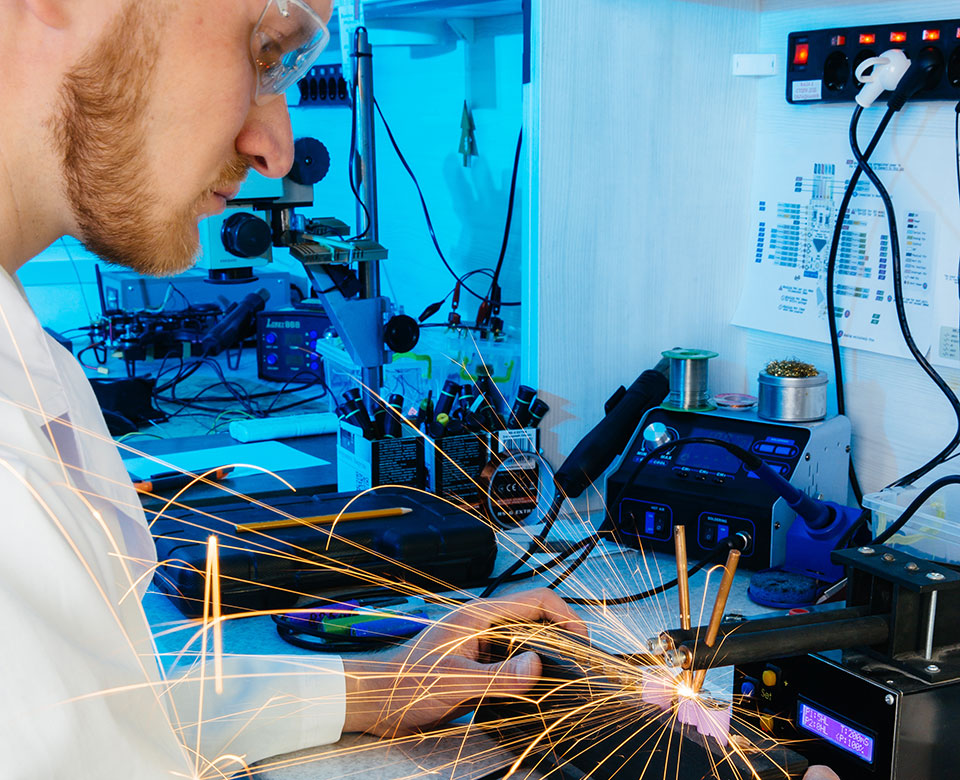

With more than 25 years of Printed Circuit Board Assembly design and manufacturing sales representation experience, Adcour maintains a strategic supply chain for custom – quick turn – high mix – low to mid volume Battery Management System (BMS) circuit card assemblies, ensuring total in-house control of turnkey battery system solutions.

Often our pre-production Design For Manufacturability (DFM) reviews result in recommendations to our customers that enhance product durability and reduce assembly time (with savings passed on to the customer) while maintaining the electrical performance of the design. Lab view and load simulation software systems enable Adcour and our customers’ designers to collaboratively calculate virtual performance projections based on anticipated electrical load and field environmental parameters.

Since 1968 Adcour has provided custom battery pack assembly services to the government/military, oceanographic, medical, aerospace and industrial markets, and in recent years added robotics to our customer base. As one of the first established custom battery pack assembly facilities in the United States, we have the experience and expertise to provide customers with superior quality, cost effective solutions designed and manufactured to meet their exact specifications.

Our highly trained and deeply knowledgeable production team is experienced with all major chemistries, including alkaline, lithium (lithium ion, lithium polymer, lithium primary) nickel metal hydride (NiMH) and nickel cadmium (NiCd).

With a focus on low to mid volume/high mix battery pack assembly/manufacturing, Adcour can offer the quick turnaround time our customers require for prototype, NPI and JIT production material management. A flexible and agile assembly environment allows for modifications as needed throughout the product development life cycle.

Quality is key. In reviewing our past performance, new customers will notice a common denominator – overall quality and on-time delivery customer approval ratings average 99%. These ratings are a strong indication of Adcour’s extraordinary focus on both customer service and QC and is a testament to the strength of our in-place quality management systems (QMS) and processes.

Adcour believes strongly in proper testing/quality control and operates its production facility under the auspices of our in-place QMS manual. This manual is designed to establish the specific operational controls necessary to manufacture and support the high level of quality we demand for our products and services. Our QMS manual provides the foundation for a standards-driven system of processes that adheres to ISO 9001:2015 and AS9100C requirements.

We maintain a robust in-house Engineering Test Development department. Our semi-automated test suites are configured to duplicate electrical and environmental field conditions. We are equipped to cycle battery systems while monitoring and recording performance, including thermal characteristics, allowing for accurate life cycle projections.

Please contact us for application assistance, technical data or pricing.

contact us today! REQUEST A QUOTE

Please submit your inquiry below. A member of our team will contact you shortly.